Product Description

Description

General Products Application /Service Area:

Metal parts for vehicle, agriculture machine, construction machine, transportation equipment, Valve and Pump system. E.g. Engine bracket, truck chassis bracket, gear box , gear housing , gear cover, shaft, spline shaft , pulley, flange, connection pipe, pipe, hydraulic valve, valve housing ,Fitting , flange, wheel, flywheel, oil pump housing, starter housing, coolant pump housing, transmission shaft , transmission gear, sprocket, chains etc.

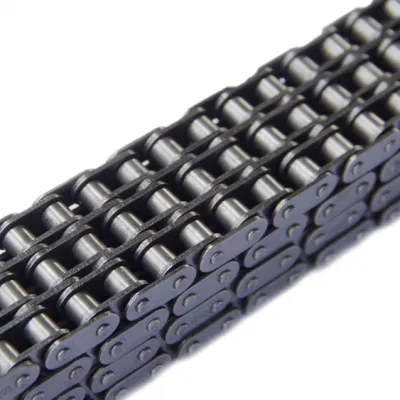

scraper conveyor chain

The scraper conveyor chain can be used to transport bulk materials in horizontal, inclined and vertical directions. It is often used for the transportation of raw grain, semi-finished products and finished products in grain and oil, feed processing plants. The scraper conveyor chain is suitable for the transportation of oil in the production process of grease processing plants. Transportation of raw grain from grain warehouse.

It has the advantages of simple structure, good sealing, simple feeding and unloading device, multi-point feeding and unloading, flexible layout, and the ability to complete material transportation in multiple directions at the same time. The scraper conveyor chain of ZheJiang CHINAMFG Chain Factory adopts medium carbon quenched and tempered steel and cold heading die steel. The steel is moderately priced and easy to process. After proper heat treatment, a certain degree of toughness, plasticity and wear resistance can be obtained. Normalizing can promote the spheroidization of the structure and is suitable for surface hardening treatments such as high-frequency quenching and flame quenching. Application: After quenching and tempering, it can be used to manufacture medium load and medium speed work. The working principle of the scraper conveyor is to use the open chute as a bearing part for coal, gangue or materials, and fix the scraper on the chain (to form a scraper chain) as a traction member. When the driving part of the machine head starts, the sprocket on the driving head shaft rotates, so that the scraper chain circulates and moves the animal material along the chute until it reaches the machine head to unload. The scraper chain bypasses the sprocket and runs in a stepless closed loop to complete the transportation of materials. Other scraper conveyor chain uses and maintenance precautions have to be communicated with the supplier. The above information is for reference only.

China chain manufacturer iron chain hardened steel chain scraper conveyor

Product Description

|

Customized Service Chain Conveyor Belt Stainless Steel |

|||||||||||||||||||||

|

Production Process |

Forging, press, plus machining ,heat treatment , assembly |

||||||||||||||||||||

|

Blanks Tolerance: |

FAQ: 1. Are you a manufacturer or a trading company? /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

What are the maintenance requirements for a bush chain?Maintaining a bush chain is essential to ensure its optimal performance and longevity. Here are the key maintenance requirements for a bush chain: 1. Regular cleaning: Regularly clean the bush chain to remove dirt, debris, and contaminants that can cause abrasion and accelerated wear. Use a brush or compressed air to clean the chain thoroughly. 2. Lubrication: Proper lubrication is crucial for the smooth operation and reduced friction of a bush chain. Apply the recommended lubricant to all the chain components, including the pins, bushings, and rollers. Follow the manufacturer’s guidelines for the appropriate lubricant type and frequency of lubrication. 3. Tension adjustment: Check the tension of the bush chain regularly and adjust it if necessary. Proper tension ensures optimal performance and reduces the risk of premature wear or failure. Consult the manufacturer’s guidelines or expert advice for the correct tensioning procedure specific to your chain. 4. Inspection: Conduct regular inspections of the bush chain to identify any signs of wear, damage, or misalignment. Inspect the chain for elongation, broken or damaged components, and misalignment. Replace any worn or damaged parts promptly to prevent further issues. 5. Replace worn components: Over time, the components of a bush chain, such as pins, bushings, and rollers, may wear out and require replacement. Monitor the wear levels of these components and replace them when they reach the manufacturer’s recommended limits. 6. Environmental considerations: Consider the operating environment of the bush chain and take appropriate measures to protect it. In corrosive or harsh environments, use corrosion-resistant chain materials or coatings to prevent accelerated wear. 7. Training and documentation: Ensure that maintenance personnel are properly trained in bush chain maintenance procedures. Keep detailed records of maintenance activities, including lubrication schedules, tension adjustments, and component replacements. By following these maintenance requirements, you can extend the lifespan of your bush chain and maintain its optimal performance. Regular maintenance and timely replacement of worn components will help prevent unexpected failures and costly downtime.

How does a bush chain handle different speeds and loads?Bush chains are designed to handle various speeds and loads in industrial applications. Here’s how they accommodate different operating conditions: 1. Speed: Bush chains are engineered to operate effectively at different speeds, ranging from low-speed to high-speed applications. The design and materials used in the chain construction ensure smooth and reliable performance even at high rotational speeds. The chain’s pitch, diameter, and strength are factors considered during the selection process to match the required speed. 2. Load capacity: Bush chains are designed to withstand different load capacities, including both static and dynamic loads. The chain’s strength, determined by factors such as the material used, chain size, and construction, is critical in handling different loads. The appropriate chain size and strength must be selected to ensure that the chain can safely and reliably transmit the required loads without deformation or failure. 3. Lubrication: Proper lubrication is essential for the smooth operation of a bush chain under varying speeds and loads. Lubrication reduces friction and wear between the chain components, allowing the chain to operate efficiently. Depending on the application, lubrication can be achieved through various methods, including manual lubrication, automatic lubrication systems, or self-lubricating bush chains. 4. Material selection: The choice of materials for the bush chain components plays a crucial role in handling different speeds and loads. High-strength materials, such as hardened steel or alloys, are commonly used for the chain plates, pins, and bushings to ensure the necessary strength and durability. Additionally, specialized coatings or surface treatments may be applied to enhance wear resistance and reduce friction. 5. Design considerations: The design of the bush chain, including factors such as the number of links, link shape, and articulation, is optimized to distribute the load evenly and promote smooth engagement with the sprockets. These design elements help minimize stress concentration points and ensure efficient power transmission. By considering factors such as speed, load capacity, lubrication, material selection, and design, bush chains are able to handle a wide range of operating conditions. Proper selection and maintenance of the bush chain are essential to ensure optimal performance, longevity, and safety in various industrial applications.

How does a bush chain differ from other types of chains?A bush chain, also known as a bush roller chain or bushing chain, differs from other types of chains in its construction and design. Here are the key ways in which a bush chain differs: 1. Bushing Design: The main distinguishing feature of a bush chain is the presence of bushings or sleeves between the inner and outer links. These bushings serve as bearings that reduce friction and wear between the chain components, resulting in smoother operation and increased chain life. 2. Simplex, Duplex, and Triplex Configurations: Bush chains are available in different configurations, including simplex, duplex, and triplex. These configurations refer to the number of strands of chain running parallel to each other. This allows for increased load capacity and higher torque transmission in the chain system. 3. Link Plate Design: The link plates in a bush chain are typically thicker and heavier compared to other types of chains. This design provides enhanced strength and durability, allowing the chain to withstand heavy loads and resist elongation under tension. 4. Precision Bushing Fit: The bushings in a bush chain have a precise fit with the pins, which ensures proper alignment and smooth rotation. This reduces friction, minimizes wear, and improves the overall efficiency of the chain system. 5. Lubrication Requirements: Bush chains usually require regular lubrication to maintain optimal performance and reduce friction between the components. Lubrication helps prevent wear and corrosion, ensuring the longevity of the chain. 6. Wide Range of Applications: Bush chains are versatile and find applications in various industrial settings, including machinery, automotive systems, agriculture, material handling, mining, and more. Their robust construction and ability to handle high loads make them suitable for demanding applications. Overall, the inclusion of bushings, the configuration options, and the design characteristics of bush chains distinguish them from other types of chains. Their unique features make them ideal for applications that require durability, high load capacity, and reduced friction for reliable power transmission.

| ||||||||||||||||||||